While guar gum powder may be familiar as a thickening agent in cooking, its versatility extends far beyond the culinary realm. This natural product has found its place in various industrial applications, playing a crucial role in sectors such as oil and gas, paper manufacturing, and textiles. Let's dive into the diverse industrial uses of guar gum powder and explore how its unique properties contribute to these applications.

Introduction

Beyond its role in the kitchen, guar gum powder boasts a wide range of industrial applications that capitalize on its unique properties. From enhancing drilling efficiency in the oil and gas industry to improving paper quality and aiding textile processes, guar gum powder's versatility and functionality have made it a valuable resource in various sectors.

The Magic of Guar Gum Powder

Derived from Guar Beans

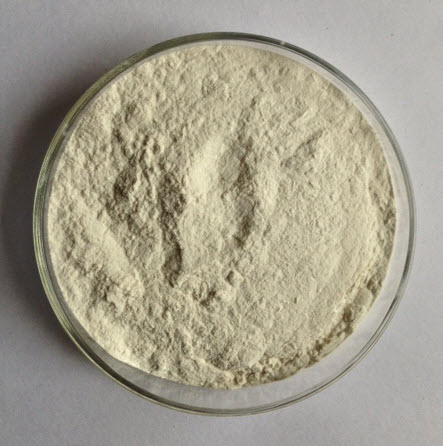

Guar gum powder is derived from the endosperm of guar beans, which are primarily cultivated in regions such as India and Pakistan. The beans undergo a series of processes, including dehusking, milling, and refining, to yield the fine powder known for its remarkable properties.

Solubility and Viscosity

The primary appeal of guar gum powder lies in its solubility and viscosity-enhancing capabilities. When mixed with water, it forms a viscous solution that can be adjusted to varying thickness levels, making it ideal for a range of industrial applications.

Guar Gum in Oil and Gas Industry

Hydraulic Fracturing Fluids

One of the most notable uses of guar gum powder is in hydraulic fracturing, or fracking. In the oil and gas industry, guar gum is added to fracturing fluids to increase their viscosity and effectively transport proppants into fractures, ensuring optimal oil and gas extraction.

Cost-Effective Drilling Aids

Guar gum powder also serves as a cost-effective drilling aid. It helps maintain the stability of drilling fluids, preventing them from collapsing into the borehole while drilling. This aids in efficient drilling and contributes to overall drilling success.

Guar Gum in Paper Manufacturing

Improving Paper Strength

In the paper manufacturing industry, guar gum powder acts as a strengthening agent. It enhances the tensile strength and tear resistance of paper, resulting in improved durability and quality of the final product.

Enhancing Print Quality

Guar gum powder's ability to control viscosity and absorbency makes it valuable in improving print quality. It is used in the formulation of printing inks and coatings, ensuring precise and vibrant printing on paper and packaging materials.

Guar Gum in Textiles

Printing and Dyeing Assistance

In the textile industry, guar gum powder assists in fabric printing and dyeing processes. It acts as a thickener and binder in dye pastes, helping to achieve consistent and vivid colors on textiles.

Fabric Sizing and Finishing

Guar gum powder is used in fabric sizing to improve the weaving process by providing stability to the yarns. It also contributes to fabric finishing by imparting softness and smoothness to the final textile products.

Unlocking Industrial Potential

Adaptability and Sustainability

Guar gum powder's adaptability to various industrial processes stems from its unique properties. Its natural origin and eco-friendly characteristics make it an attractive choice for industries seeking sustainable solutions.

Innovations and Research

As industries continue to evolve, ongoing research and innovation explore new ways to utilize guar gum powder. Whether in enhancing drilling efficiency, improving paper quality, or aiding textile processes, guar gum powder's potential is far-reaching.

Conclusion

Guar gum powder's role extends well beyond the kitchen, infiltrating industries where its unique properties are harnessed for various applications. From enabling efficient oil extraction to enhancing paper strength and contributing to vibrant textiles, guar gum powder demonstrates its versatility and adaptability in diverse industrial sectors. As industries continue to innovate and seek sustainable solutions, guar gum powder remains a valuable resource that contributes to efficiency, quality, and progress across the industrial landscape.

Web Design & Digital Marketing by Opal Infotech