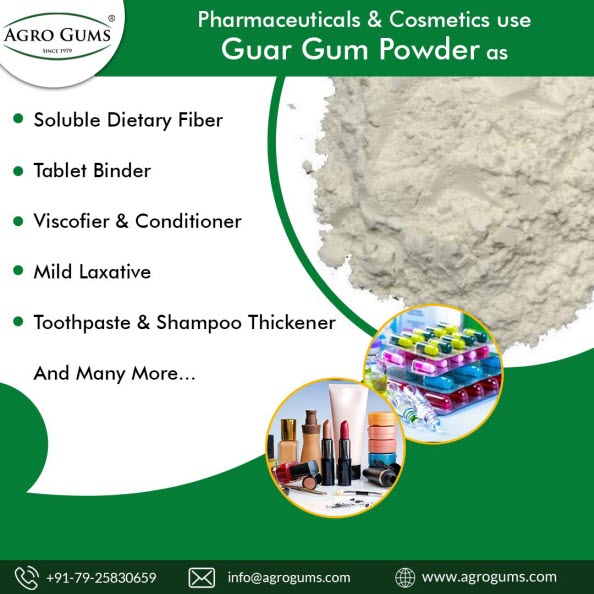

Guar gum powder, a natural thickening and stabilizing agent derived from guar beans, has found a significant place in the pharmaceutical industry. In this article, we will explore the various applications of guar gum powder in pharmaceutical formulations and discuss its properties, advantages, and production.

What is Guar Gum Powder?

Guar gum powder is a natural substance obtained from guar beans (Cyamopsis tetragonoloba), which are primarily grown in India and Pakistan. It has been used for centuries, with its roots dating back to ancient times. Guar gum is water-soluble and is often used as a thickening and binding agent in various industries.

The Origin of Guar Gum Powder

The history of guar gum powder dates back to the Indian subcontinent, where it was traditionally used in cooking and various folk medicines. Its use as a food additive and industrial product gained momentum in the 20th century.

Properties of Guar Gum Powder

Guar gum possesses several unique properties that make it suitable for pharmaceutical applications. These properties include its ability to form gels, bind with water, and provide viscosity to solutions. These characteristics are highly beneficial in pharmaceutical formulations.

Guar Gum in Pharmaceutical Formulations

Binding Agent

One of the key applications of guar gum in pharmaceuticals is its use as a binding agent. It helps in holding the active pharmaceutical ingredients (APIs) together in solid dosage forms like tablets and capsules.

Viscosity Control

Guar gum is also known for its viscosity-enhancing properties. It can increase the thickness of liquid formulations, making them easier to administer and improving their stability.

Sustained Release

In pharmaceutical formulations, sustained release is crucial for drugs that need to be released gradually over time. Guar gum's ability to control viscosity can be harnessed to achieve a sustained release effect, ensuring that the drug is delivered at a controlled rate.

Advantages of Using Guar Gum in Pharmaceuticals

Natural and Safe

One of the primary advantages of using guar gum in pharmaceuticals is its natural origin. It is considered safe for human consumption and doesn't pose any health risks.

Cost-Effective

Compared to synthetic thickeners and binders, guar gum is cost-effective, making it an attractive option for pharmaceutical companies looking to reduce production costs.

Applications of Guar Gum in Medicines

Tablets and Capsules

Guar gum is commonly used in the manufacturing of tablets and capsules. It provides cohesiveness to the formulation, ensuring that the tablet remains intact until ingestion.

Liquid Formulations

In liquid medicines, guar gum is employed to control viscosity and prevent settling of suspended particles. This ensures that the drug is evenly distributed in the solution.

Guar Gum Powder Production

Guar gum is extracted from guar beans through a multi-step process, including dehusking, grinding, and sieving. The resulting powder is then further refined to meet the required specifications for pharmaceutical use.

Quality Control in Pharmaceutical Guar Gum

Maintaining high-quality standards is imperative in the pharmaceutical industry. Guar gum used in pharmaceutical formulations undergoes rigorous quality control checks to ensure its purity and effectiveness.

Challenges and Concerns

While guar gum offers numerous advantages, there are challenges, such as variations in quality due to environmental factors. Pharmaceutical companies need to work closely with guar gum suppliers to maintain consistency in their products.

Conclusion

In conclusion, guar gum powder has found a valuable place in pharmaceutical formulations. Its role as a binding agent, viscosity controller, and sustained release agent makes it an indispensable ingredient in the pharmaceutical industry.

Frequently Asked Questions (FAQs)

Web Design & Digital Marketing by Opal Infotech